Kronalux® 2K-Rolling plastic 763

Cold plastic: High-quality marking paints for long-lasting surface markings

- For full-surface markings, even on asphalt

- Non-slip thanks to high-grip material

- Excellent visibility during the day and at night – even in wet conditions!

- For very long-lasting markings

- Easy to apply

- Can be tinted according to RAL

2K Roll Plastic is a solvent-free, two-component cold plastic based on acrylic polymers. Kronalux® 2K Roll Plastic is particularly suitable for producing surface markings with slightly textured and non-slip surfaces.

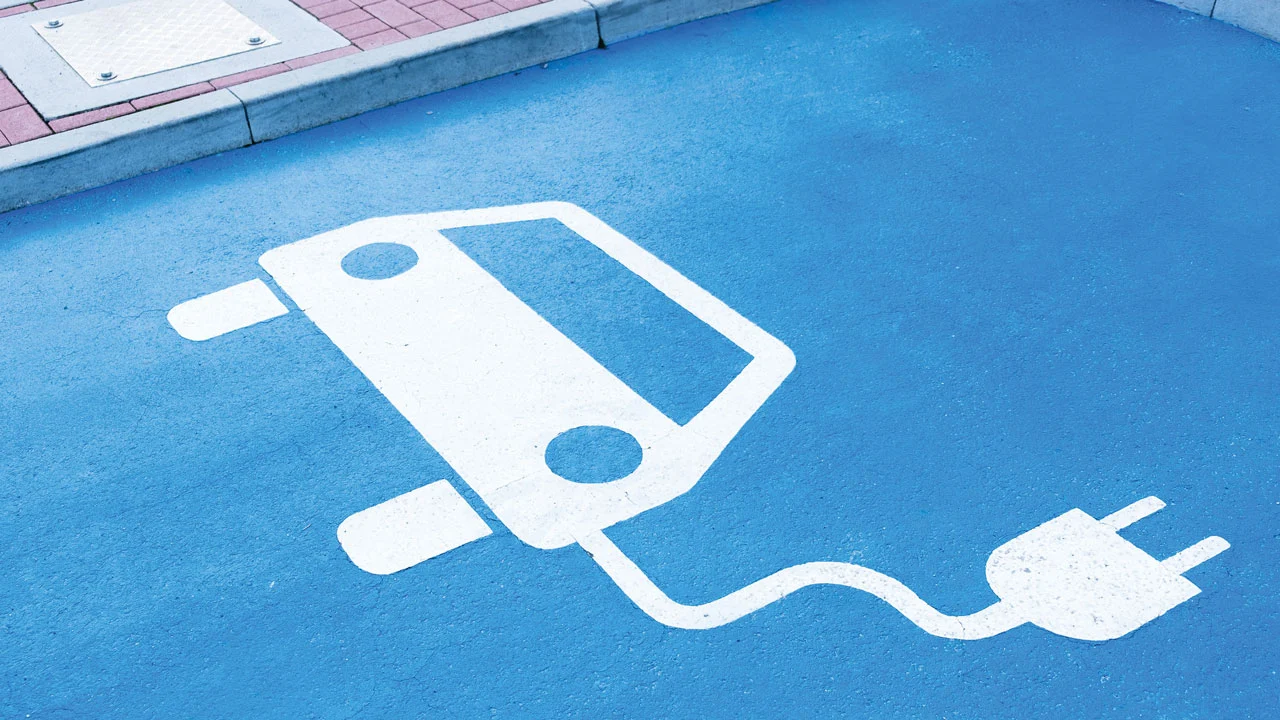

Video | Parking space marking for electric cars with JAEGER's 2K roll plastic

Pot life: approx. 10 minutes at 20°C (shorter pot life at higher temperatures)

Mixing ratio: 99 : 1 (parts by weight) with peroxide hardener

Substrate preparation

Coatings on concrete, screed, asphalt

Mineral substrates must be well cured before starting painting work; new concrete must be at least 4-6 weeks old. The substrate must be dry, clean, free of grease, and sound; loose and sandy layers must be removed. Concrete and screed must still be sufficiently absorbent to ensure adhesion. Any cement paste or sintered layers on the surface must be removed by sandblasting or milling. Oily concrete surfaces that have already been used are best cleaned by brushing with Jaeger 080 Special Cleaner or alkaline cleaning agents. Rinse with plenty of water or a steam jet. Allow surfaces to dry thoroughly. Moisture on the reverse side will impair adhesion. Concrete and screed should be primed with 864 Special Primer Resin. Asphalt must be thoroughly cleaned with a high-pressure cleaner to ensure good adhesion. Sand down old coatings; we recommend preliminary tests to check adhesion. Not suitable for glass. Carry out preliminary tests on plastics.

Coating

1x with spatula and textured roller

Note: When marking the entire surface, cracks may form on asphalt under strong sunlight, especially on new asphalt. Cracks may form in the joints of paving stones.

Processing conditions

During the entire application and drying time, the material, substrate, and air temperature must not fall below 8°C or exceed 30°C. The air humidity should be between 30% and 75% relative humidity during the entire time.

If necessary, sprinkle 759 (800 g/m²) immediately after application. Maintain a layer thickness of 1.8 mm.

product data

spreading rate

| paint/roll | spraying |

|---|---|

| 0,33 m²/kg |

item number/shade

| item number | shade |

|---|---|

| 763-0800 | Weiß |

| 763-0009 | Base Transparent |