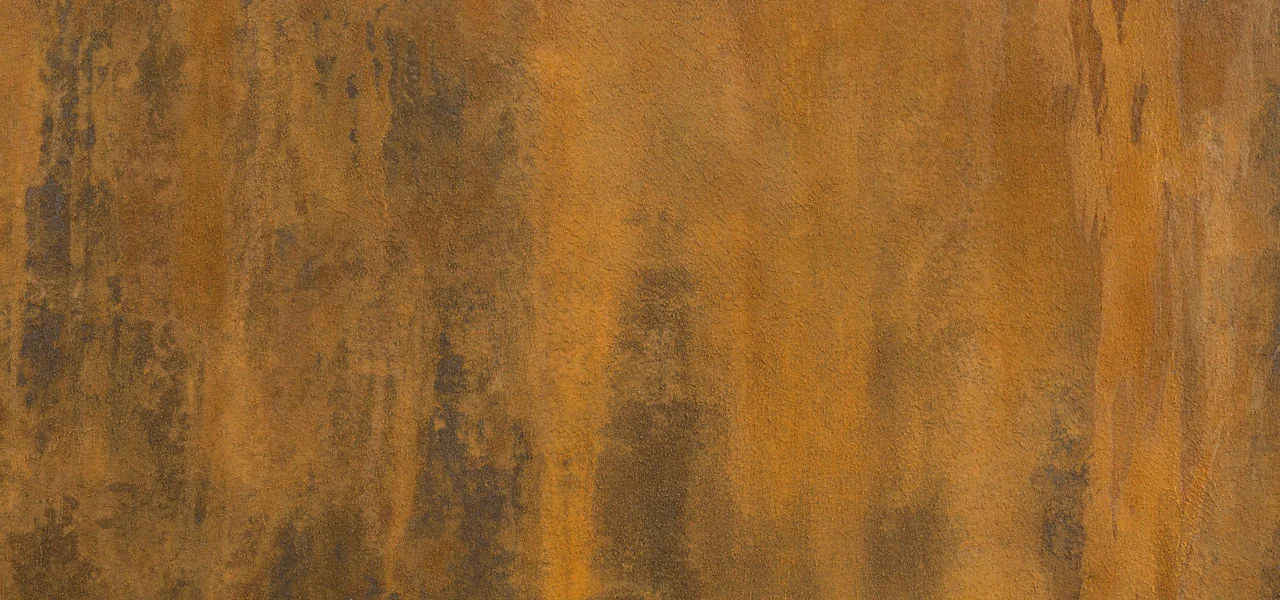

Real Rust 986

Rust paint with a real rust effect for painting.

Rusty surfaces are essential for the industrial style. Now, real rust can be created quickly, easily and particularly, in a targeted manner: The primer, which is provided with iron particles, is oxidised using a separately supplied activator. The strength of the effect can be controlled by the application method of the activator. Then, the surface can be protected from discoloration with a protective coating.

Purpose:

Real-rust 986 enables the design of decorative surfaces by means of oxidation of iron particles, e.g. on walls, ceilings or exposed surfaces. Depending on the application method of the activator, the rust effect can be designed individually.

Properties:

Decorative appearance, real rust surface, individual design options, easy to apply

Preparation and application of rust paint

1. Prepare the surface

The surface must be dry, clean, and stable. Consolidate highly absorbent surfaces with a deep primer. Not suitable for alkaline surfaces (e.g., fresh concrete). Iso-Mineralgrund 309 creates an even surface as an adhesive primer.

2. Base color

Rust effect base color Stir the real rust base color well and dilute with 30% water (300 ml water to 1 l base color). Apply two to three coats with a roller, allowing each coat to dry for at least four hours. Then allow to dry overnight (at least 12 hours).

3. Activator

Apply the activator to the base color using a brush, roller, natural sponge, or pump spray bottle. After allowing to dry for two hours, the activator can be applied again. The amount of activator determines the final appearance; the activator can be applied as often as desired after drying. The final appearance develops over the next few hours. The activator works as long as it is moist. If an intense rust appearance is desired, it is advisable to protect the surface with a film after applying the activator to prevent it from drying out until the desired effect is achieved.

Sealing (optional)

After a drying time of at least 48 hours, the real rust surface can be coated with Real Rust Seal 925 (diluted with approx. 50% water) in indoor areas. Dust the surface before sealing and apply the sealant thinly. The sealant protects the surface from discoloration and slightly fires the substrate depending on the degree of dilution.

Caution: Only one coat of activator should be applied before sealing. Applying multiple coats of activator will cause incompatibility with the sealing varnish, which will then turn milky.

For heavily used surfaces and areas in wet areas, seal twice with Echt-Rost-Siegel 925 (50% diluted with water) and then twice with 2K-Aqua Nassraumsiegel. For surfaces in shower areas, the substrate must be prepared in accordance with current standards (DIN 18534 – Waterproofing of interior rooms).

Our rust effect paint makes many other interior paints look quite old.

It allows you to create decorative surfaces through the oxidation of iron particles, for example on walls, ceilings, or exposed surfaces. The base paint is easy to apply and is oxidized using the activator (500 ml) supplied. If a stronger rust effect is desired, the activator is also available separately.

The intensity of the rust effect can be precisely controlled and customized depending on how the activator is applied. The paint offers a decorative appearance with a genuine rust surface and a wide range of design options. To protect the surface from discoloration, our Real Rust Seal is applied as a final coat, which provides a colorless seal and ensures good abrasion resistance and high light fastness both indoors and outdoors. For a wow effect that lasts.

product data

spreading rate

| paint/roll | spraying |

|---|---|

| 3-6 m²/l |

item number/shade

| item number | shade |

|---|---|

| 986-0000 | Echtrost |

size of trading unit/box content

| size of trading unit | box content |

|---|---|

| 1 l | 1 |