Kronen® Gold Varnish - Silver Varnish - Copper Varnish 246

Metallic lacquer in gold, silver, copper for indoor and outdoor applications.

Kronen® gold varnish, silver varnish, copper varnish is a decorative metallically glossy varnish for the finishing surfaces of all kinds. Weatherproof, quick drying, easy to apply and temperature resistant up to 80°C. The metallic colour is suitable for metal, plastic, wood and glass.

Properties:

- metallically glossy surface

- easy to apply

- for inside and outside

- quick-drying

- temperature resistant up to 80°C

- wipe-resistant

- firm to the touch

- weather-resistant

Processing instructions for gold lacquer, silver lacquer, and copper lacquer

Substrate preparation

Before applying Kronen® gold lacquer, silver lacquer, or copper lacquer, the substrate must be clean, dry, grease-free, and stable. Rust, scale, and milling burrs must be removed. Old paint coats should be cleaned, sanded, and checked for recoatability. Absorbent substrates must be primed beforehand. Steel should be protected against corrosion, for example with a universal primer such as Jaeger Multigrund 715 or a primer spray such as Multigrund Spray 715. These paints are suitable for many metals, wood, plastics, and glass. Preliminary tests are recommended to test compatibility.

Processing

Before applying Kronen® Gold Paint, Silver Paint, or Copper Paint, the paint should be stirred well, and occasional stirring is also advisable during processing. The paint is applied in 1-2 coats by brushing, rolling, or spraying, with an intermediate drying time of at least 24 hours.

During the entire processing and drying time, the material, substrate, and air temperature must not fall below 10°C or exceed 30°C. The air humidity should be between 30% RH and 75% RH throughout the entire period. High temperatures and low humidity accelerate drying, while low temperatures and high humidity delay drying.

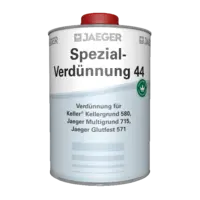

Thinning

The product is ready for use, if necessary with Nitro Thinner 044 or Universal Thinner.

Drying (20°C)

- Dust dry approx. 60 minutes

- Through-dry approx. 48 hours

Special instructions: Adhere to the recommended application quantity; excessive layer thickness will result in longer drying times.

product data

spreading rate

| paint/roll | spraying |

|---|---|

| 7-8 m²/l |

item number/shade

| item number | shade |

|---|---|

| 246-0700 | Gold |

| 246-0701 | Silber |

| 246-0704 | Kupfer |

| 246-0700 | Gold |

| 246-0701 | Silber |

| 246-0704 | Kupfer |

size of trading unit/box content

| size of trading unit | box content |

|---|---|

| 375 ml | 6 |

| 750 ml | 6 |

| 375 ml | 6 |

| 750 ml | 6 |

| 375 ml | 6 |

| 750 ml | 6 |